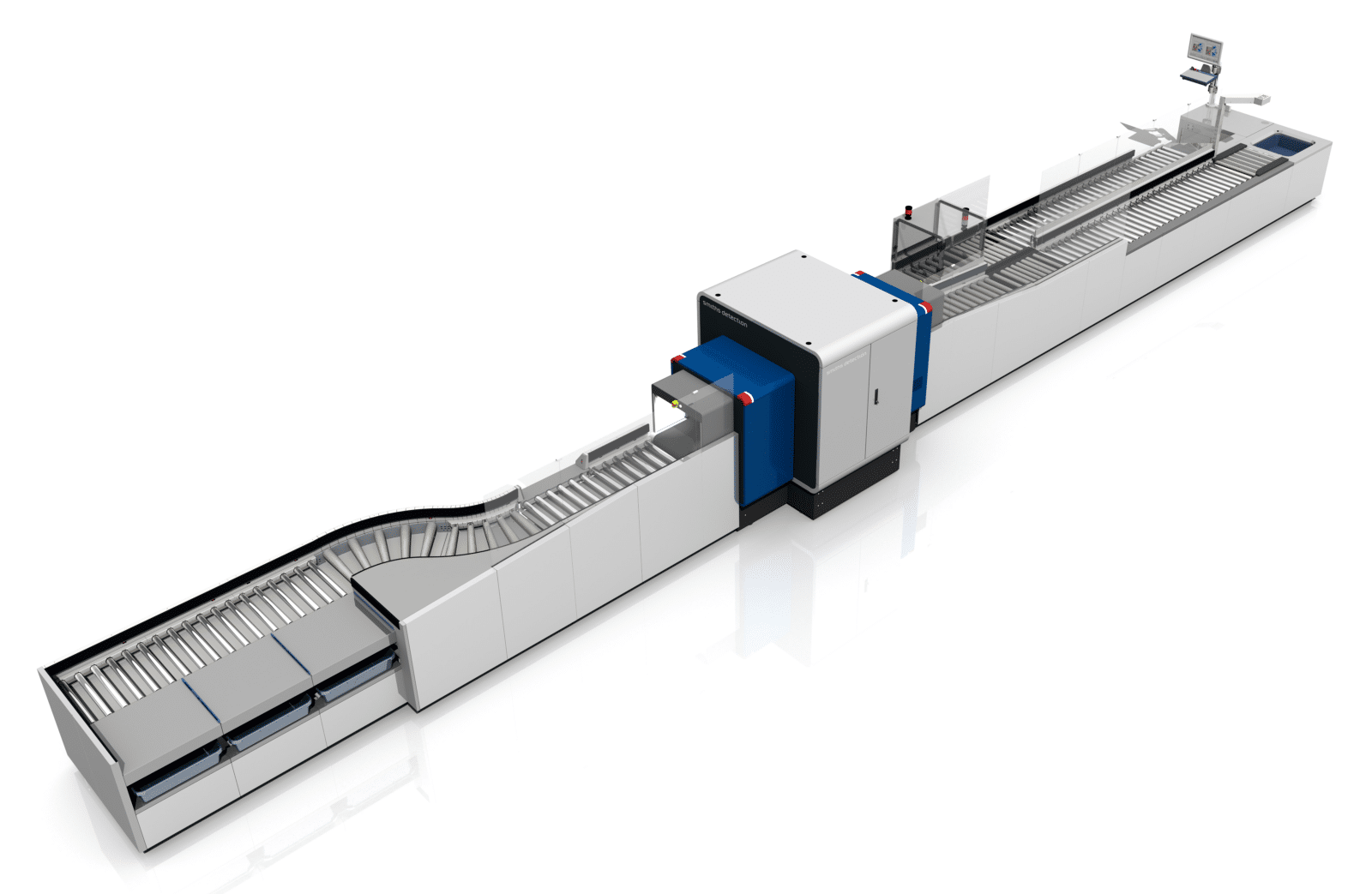

Smiths Detection has launched its next generation smart tray return system, the iLane A20. The fully automated system aims to increase throughput, reduce queues and improve operational efficiency at airport passenger checkpoints.

Smiths Detection, in collaboration with material handling solutions provider Interroll, has based the new model on existing iLane tray return systems.

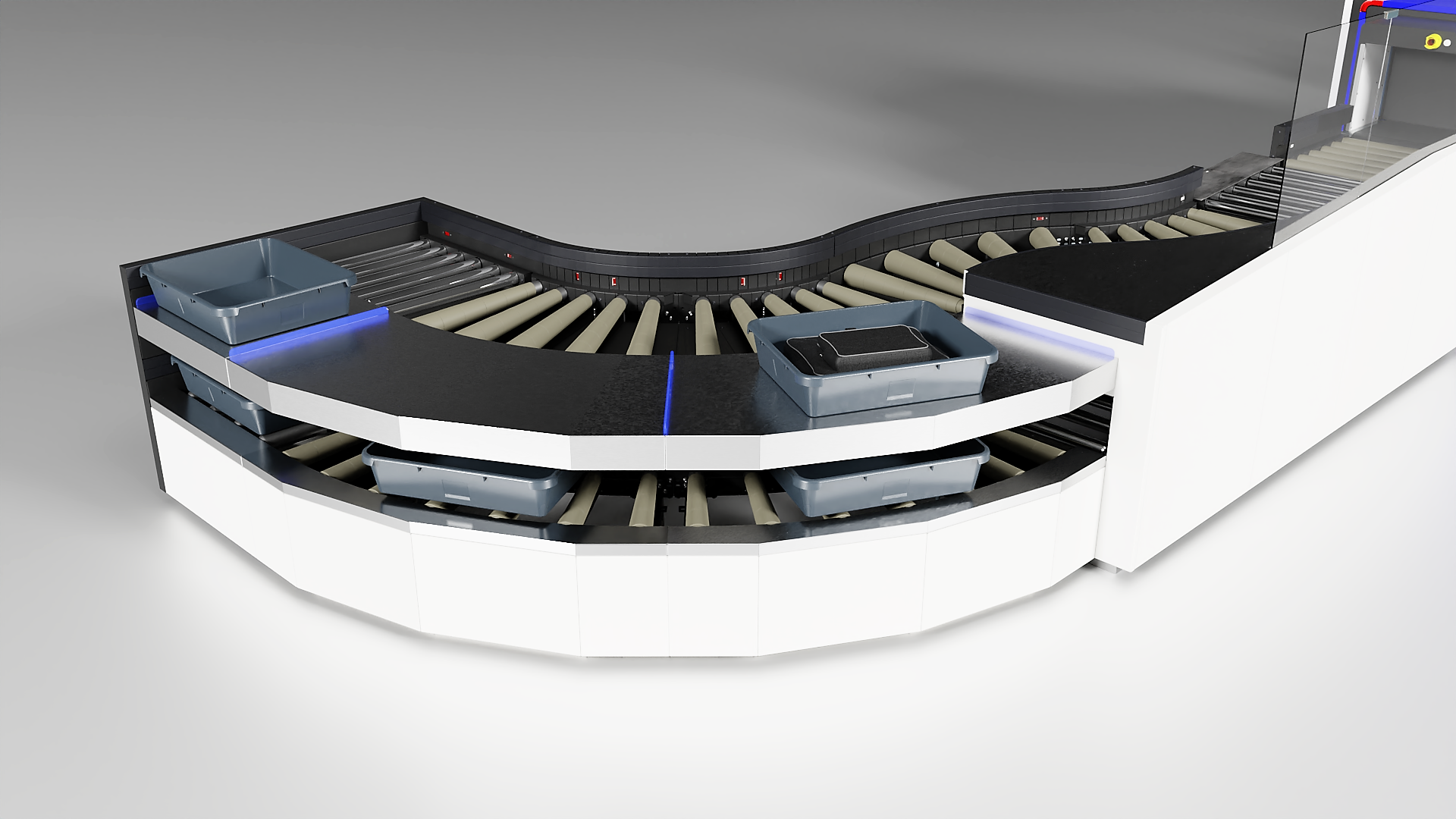

Features of the new system include parallel divest, enabling simultaneous passenger screening, empty tray verification and the diversion of suspicious baggage. A cost effective solution, it also removes the need to replace the whole lane for upgrades, while its modular design offers customisation to suit bespoke throughput levels, aesthetic requirements and space restrictions.

With UK airports set to shake up baggage security screening rules by axing the need to remove liquids and laptops from hand luggage by 2024 thanks to high-tech 3D scanners, the iLane A20 can also utilise Smiths Detection’s Universal Checkpoint Interface to support the implementation of third-party X-ray systems, improving airports’ agility for meeting these new operational requirements.

Commenting on the iLane A20, Daan Van Vroonhoven, Global Director of Aviation, Smiths Detection, said: “As the aviation industry continues to recover from the pandemic, efficiency and passenger experience are more important than ever.

“This new system meets the most demanding of operational environments, supporting a seamless, passenger friendly screening process by removing bottlenecks and improving staff productivity, all while reducing operational costs.”